About Us

Improve the Accuracy and Durability of Crimping Hydraulic Hose Assemblies

Views : 38

Update time : 2025-12-24 14:50:00

How to Improve the Accuracy and Durability of Crimping Hydraulic Hose Assemblies?

I. Why are crimping accuracy and durability so important?

Crimping quality directly determines:Whether there is leakage

Whether there is premature failure

Whether it passes the pulse life test

Whether there are safety risks such as pull-out or hose bursting

90% of hose failures are related to the crimping process, not the hose itself.

II. Key Methods to Improve Crimping Accuracy

Precise Control of Crimping DiameterStrictly follow the crimp OD recommended by the hose and fitting manufacturer.

Use a crimping machine with clear graduations and high repeatability.

Avoid "crimping based on experience" or relying solely on pressure values.

Select Matching Dies

The die size must strictly match the hose specifications.

The die should ensure 360° uniform compression.

Regularly check die wear.

Die wear = uneven crimping = early leakage.

Ensure Full Insertion of Hose and Fitting

Before crimping, confirm that the hose is properly inserted into the fitting core.

Mark the insertion depth if necessary.

Avoid "false crimping" after crimping.

Stable and Controllable Crimping Process

Use a crimping machine with a stable hydraulic system.

Avoid pressure fluctuations or impact crimping.

Ensure a smooth and synchronized crimping process.

This is also where machine quality differences are most obvious.

III. Key Points for Improving Hose Durability

Correct Hose and Fitting SelectionWorking Pressure ≥ System Maximum Pressure × Safety Factor

The fitting structure must match the hose structure (number of wire layers, inner diameter).

Even the best crimping machine cannot save you from a wrong selection.

Controlling Appearance and Deformation After Crimping

After crimping, check:

For cracks in the crimped area

For excessive flattening

For cuts on the outer adhesive

Abnormal appearance = potential failure risk

Sampling Inspection and Testing

Pull-off Test

Impulse Life Test

Pressure Test

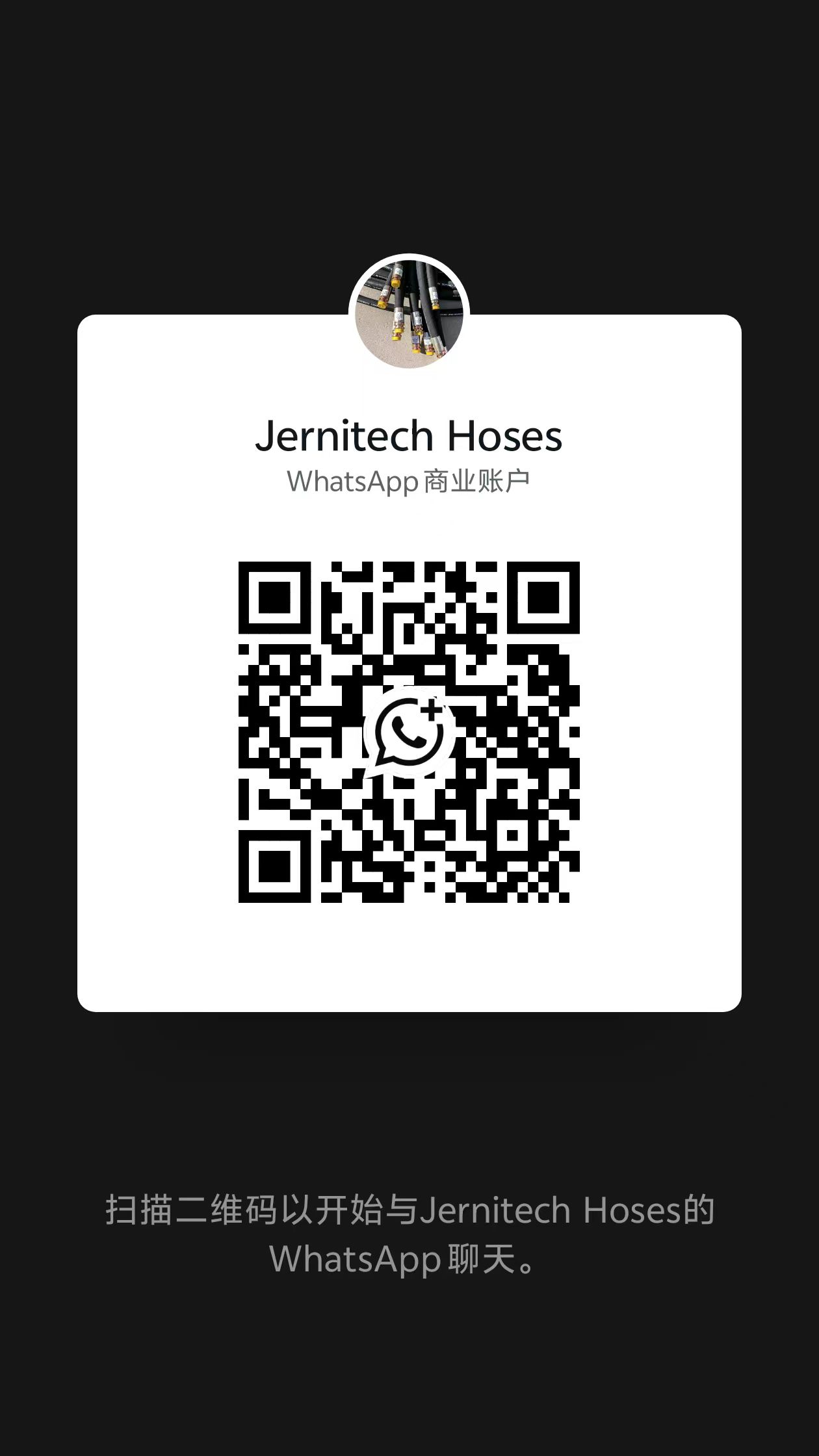

We supply completely meeting Eaton standard hydraulic hose crimping machine, as a leading one-stop sourcing supplier, we supply hydraulic hose, hose fittings, hose assembly etc. Welcome to contact us at any time.

相关新闻